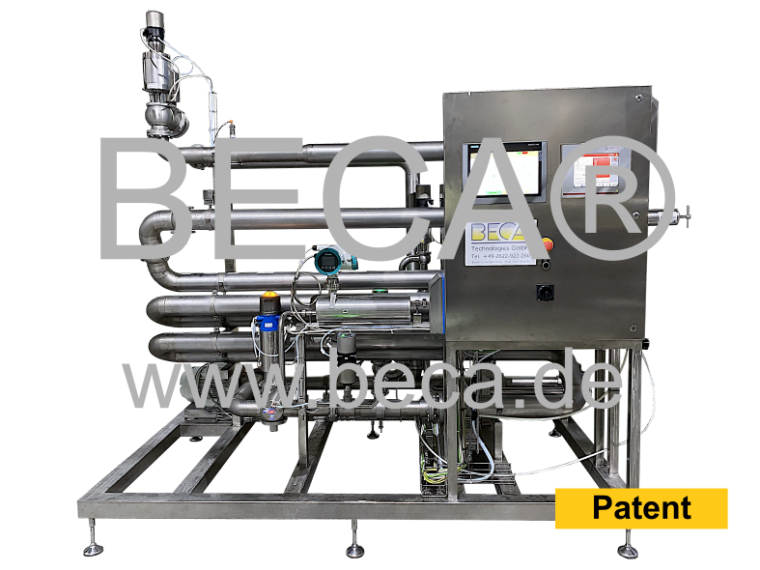

Carbonation Carbojet

System BECA®

The innovative and patented Carbonation System BECA® provides accurate CO2 dosing and control. It is not affected by variations in pressure, flowrate or interruptions in the supply of product.

CO2 is injected into the constant circulation stream by means of a special BECA® injector, which increases the turbulence and therefore the mixing intensity. The plant will continue to run even when output is interrupted, and thus guarantees exact CO2 content all the time.

The system disrupts any laminar flow of the product to be carbonated. CO2 dissolves more readily in the product under turbulent conditions. This increases the contact area between the gas and the liquid and produces a stable CO2/product mix.

There are no dead-legs. The unit is cleaned as part of the CIP of the product circuit.

Your at-a-glance benefits of using the Carbonation CarboJet System BECA®:

- Exact CO2/N2 dosing at most difficult condition of production, esp. if installed close to the filling unit

- Absolute independence of stops in drawing off / filling stops, variations of flow rates and varying pressure and temperature

- Balance free from phase shifting of different CO2/N2 contents of the pre run

- Perfectly homogenised and bubble-free CO2/N2–dissolving at lowest differential pressure by means of the BECA®-Carbonation unit Carbo-Jet

- Absence of dead-legs. Can be cleaned and sterilized inline by local CIP stations

- Easy menu-driven operation and saving of recipes

- Fully automatic processes with balancing

- Individual adaptation of the plant concept to customer requirements